how drilling machines from simple hand tools

Garage Doors and Parts – From its humble origins as a hand-powered tool to its modern-day industrial applications, the drill remains a cornerstone of technological progress.

The concept of drilling dates back thousands of years. Early humans used sharpened stones to bore holes in wood, shells, and bones. Over time, manual bow drills and hand-cranked devices evolved, marking humanity’s first steps toward mechanical precision. The industrial revolution in the 18th and 19th centuries transformed drilling from a manual craft into an automated process. The invention of the mechanical drill press allowed for deeper, cleaner, and more consistent holes revolutionizing industries like shipbuilding, mining, and machinery manufacturing. Today, advanced CNC (Computer Numerical Control) drilling machines can perform operations with micron-level accuracy, showcasing how far this simple machine has come.

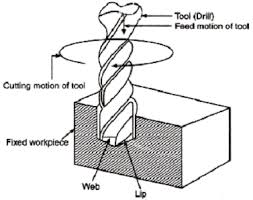

At its core, a drilling machine functions through the basic principles of rotational motion and applied force. The primary components include:

Drill Bit: The cutting tool that penetrates the material. Bits vary in shape, size, and material depending on the application from high-speed steel to diamond-tipped varieties.

Spindle: The rotating shaft that holds and drives the drill bit.

Chuck: A clamp-like mechanism that secures the drill bit in place.

Feed Mechanism: Controls the downward pressure and depth of the drilling process.

Motor: Provides the rotational energy that drives the spindle.

The result is a clean, precise hole essential in countless industrial processes.

Drilling machines come in many forms, each designed for specific tasks and materials:

Bench Drilling Machine: Compact and ideal for small-scale or precision work in workshops.

Pillar (Column) Drill: A larger, floor-mounted version capable of handling tougher materials.

Radial Drilling Machine: Equipped with a movable arm for drilling large or irregularly shaped components.

CNC Drilling Machine: The most advanced type, operated via computerized programming for automated, high-precision manufacturing.

Each type reflects how the core principle of drilling rotation and pressure has been adapted to meet the growing demands of industrial efficiency.

Drilling machines play an indispensable role across multiple industries.

Manufacturing: From assembling car engines to fabricating metal parts, drilling ensures structural integrity and precision.

Construction: Used to create holes for bolts, pipes, and reinforcements in steel and concrete structures.

Mining and Exploration: Heavy-duty drilling rigs penetrate the earth’s surface to extract minerals, oil, and natural gas.

Aerospace and Defense: High-precision CNC drills craft components for aircraft and spacecraft, where accuracy can determine safety.

Electronics: Micro-drilling technology creates holes in printed circuit boards (PCBs), vital for modern gadgets.

These diverse uses illustrate how one mechanical principle can power multiple sectors — each innovation building upon centuries of engineering progress.

Incorrect speed settings, poor alignment, or inadequate cooling can cause excessive wear on drill bits or damage to materials.

To ensure efficiency and safety, operators must:

Use the correct drill bit for the material.

Maintain proper rotational speed and feed rate.

Wear protective equipment like goggles and gloves.

Technological progress continues to refine the art and science of drilling. The integration of automation, robotics, and artificial intelligence has turned drilling into a precise, data-driven process.

Smart Sensors: Monitor vibration, torque, and temperature to predict tool wear and prevent damage.

3D Drilling Simulation Software: Allows engineers to model drilling paths digitally, reducing waste and improving efficiency.

Sustainable Drilling Technologies: Focus on minimizing energy use and recycling cooling fluids, aligning with global green manufacturing standards.

The enduring relevance of the drilling machine lies in its simplicity and adaptability. From crafting spacecraft components to constructing skyscrapers, drilling machines remain at the heart of global innovation. They are the quiet workhorses of progress transforming raw materials into tools, structures, and technologies that shape the modern world.

The drilling machine is proof that even the simplest mechanical principles can power extraordinary technological leaps. What began as a manual tool has evolved into a symbol of industrial precision and innovation. As industries continue to push boundaries with automation and smart manufacturing, the humble drill once turned by hand stands as a reminder that great progress often begins with a single, well-placed turn of the wheel.

This website uses cookies.